Breaking the plane of a PRCS (Flammable atm) w/Video

It is a common question... why does OSHA define entry as...

This work took place on a ship in a flammable atmosphere. In the video, we can see the worker sitting on the edge of the manway, with his legs dangling down inside the space. He was using a grinder to "recondition" the threads on the bolts (they corrode over time). There were no sparks generated by this work. However, the grinder's electrical motor sucked in vapors from the space and ignited the space, lifting the worker approximately 12' in the air and burning off most of his clothing. The worker did not survive. Membership Content

Fatal Reffer Explosion in GA (Updates)

It has been 1-month since the tragic death of Greene County Fire Rescue Battalion Chief Chris Eddy in GA while working a semi-truck fire on the side of the roadway. We still have not received any formal information on this event, but there has been some erroneous reporting. Out of respect for Mr. Eddy, I promised to wait for official word on this accident's cause and contributing factors. But some of this "official reporting" is just wrong. He was opening the back doors when the explosion occurred. We can see this in the frame-by-frame analysis of the accident video (Members can see this frame-by-frame video still images below). I also mentioned at the time that this was a truckload of frozen chickens, meaning the container was "refrigerated," and that we have a history of containers exploding due to flammable or improper refrigerant mixtures. Members can read: Contaminated/flammable refrigerant is suspected in refrigerated container explosions How does leadership of health and safety make a difference? (Video)

Contaminated/flammable refrigerant is suspected in refrigerated container explosions

According to reports, thirteen (13) explosions, three (3) of which involved fatalities, occurred over the past ten (10) years, leading to the grounding of hundreds of refrigerated containers worldwide. The causes of the explosions were investigated and thought to have been caused by contaminated or incorrect refrigerant being added to the refrigeration system while it was in service in Vietnam. EPA RMP citations @ food ingredients facility (NH3, H2 & $207K w/ $122K SEP)

Respondent is the owner and operator of a facility that has more than 10,000 pounds of anhydrous ammonia and Hydrogen in processes. Information gathered during the EPA inspection revealed that Respondent uses anhydrous ammonia in the production of food ingredients and produces and stores hydrogen, and therefore, is engaged in a process at its facility. Allegations of Violation EPA RMP/EPCRA citations @ food facility (NH3 & $178K)

Respondent owns or operates the AMPI production facility that uses anhydrous ammonia in its refrigeration processes. From December 20, 2021, to May 17, 2022, EPA conducted an offsite compliance monitoring investigation of the Facility. During that investigation, the EPA representatives identified alleged violations of section 112(r)(1) of the CAA and section 312 of the EPCRA. EPA'S ALLEGED VIOLATIONS OF LAW Pressure Safety Valve/Relief Valve Installation Failure

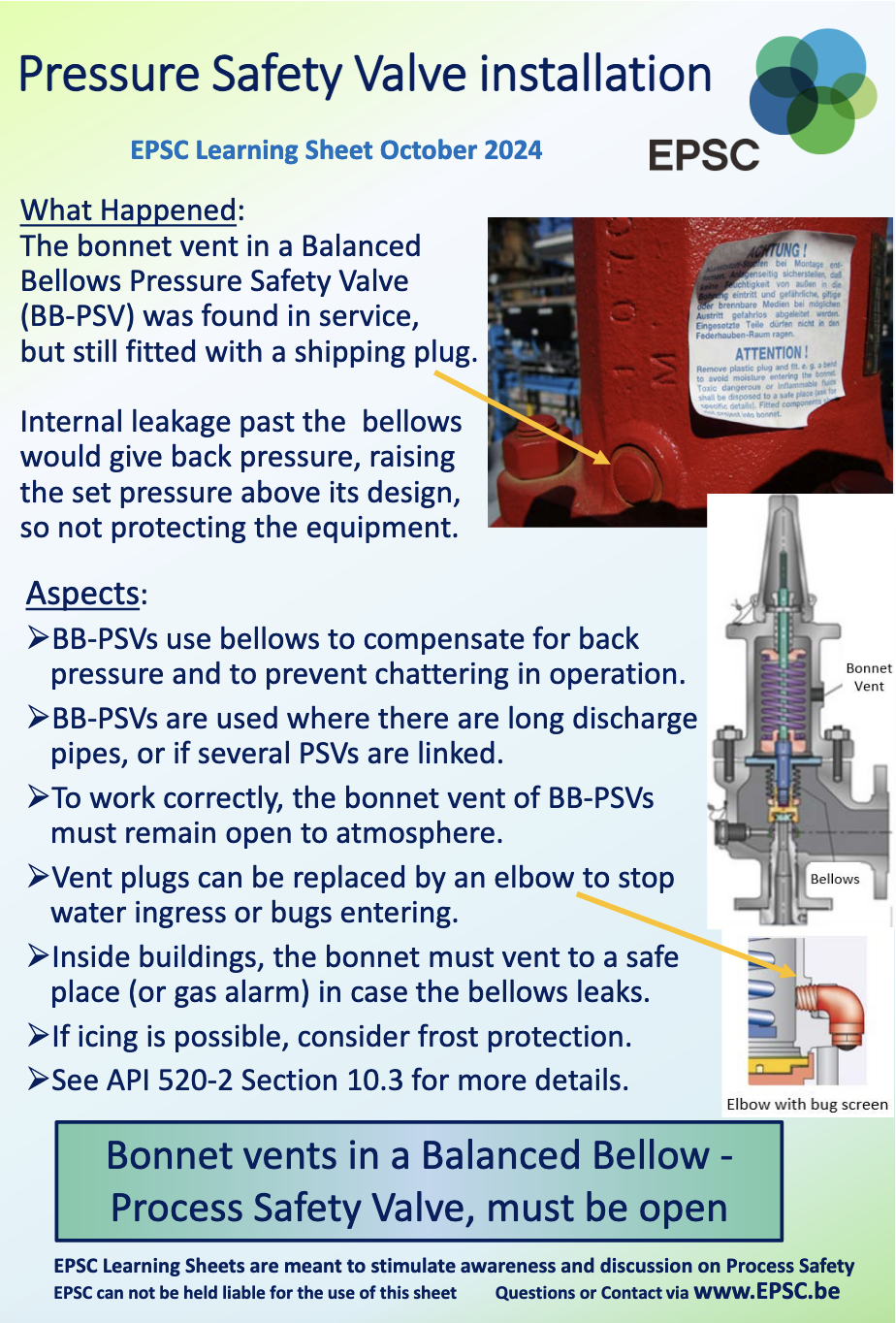

From the EPSC Learning Sheet October 2024

What Happened: The bonnet vent in a Balanced Bellows Pressure Safety Valve (BB-PSV) was found in service, but still fitted with a shipping plug. Internal leakage past the bellows would give back pressure, raising the set pressure above its design, so not protecting the equipment.

The ANSWER... Decommissioning is the final stage of a Process Life Cycle

The refrigeration system at the facility includes ammonia condensers and connected ammonia piping. Their function is to expel the heat from the ammonia vapor that will To replace a component of the refrigeration system, the ammonia in that system needs to be isolated, removed and purged before work can proceed. Decommissioning of a regulated product including ammonia refrigeration systems is regulated work. Licensed contractors must assess the associated risks with the work and ensure they are effectively mitigated and controlled before proceeding. Safety Thought of the Week (from Richard I. Cook, MD)

Catastrophe requires multiple failures – single-point failures are not enough EPA RMP citations @ metal alkyl manufacturing facility (Toxics & $125K)

Respondent is the owner and operator of a facility where EPA inspected from May 17 to May 19, 2022, to determine Respondent's compliance with Section 112(r) of the CAA and 40 C.F.R. Part 68 ("the Inspection"). The Respondent's facility is a metal alkyl manufacturing facility. The facility produces a variety of highly reactive metal alkyls including aluminum, magnesium, boron, zinc, gallium, and indium-based products. A solvent recovery process recovers solvents from plant waste streams and produces poly-aluminum chloride as a saleable byproduct. The Respondent's RMP program level 3 covered processes store or otherwise use a regulated substance in an amount exceeding the applicable threshold. EPA Alleged Violations EPA RMP GDC @ food facility (NH3 & $119K w/ $300K SEP)

Respondent was the “owner or operator” of the Facility. The Facility’s refrigeration system used approximately 5,913 pounds of anhydrous ammonia. Accordingly, at the time of the violations alleged herein, Respondent operated a stationary source that handled and stored anhydrous ammonia, listed at 40 C.F.R. § 68.130, and thus was subject to the General Duty Clause found in section 112(r)(1) of the CAA. Because of the potential hazards posed by the mishandling of anhydrous ammonia, industry trade associations have issued standards outlining the recognized and generally accepted good engineering practices in the ammonia refrigeration industry to control the risks associated with the use of ammonia, specified in Appendix A. In collaboration with the American National Standards Institute (ANSI), the International Institute of Ammonia Refrigeration (IIAR) has issued (and updates) Standard 2: Standard for Safe Design of Closed-Circuit Ammonia Mechanical Refrigeration Systems (IIAR 2), Standard 4: Installation of Closed-Circuit Ammonia Mechanical Refrigeration Systems (IIAR 5) Standard 6: Standard for Testing, Inspection, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems (IIAR 6), and Standard 9: American National Standard for Minimum System Safety Requirements for Existing Closed-Circuit Ammonia Refrigeration Systems IIAR 9), along with other applicable standards and guidance. On January 13, 2020, an authorized representative of the EPA conducted an inspection of the Facility to evaluate compliance with section 112(r) of the CAA, 42 U.S.C. § 7412(r)(1) (Inspection). The Inspection and EPA’s review of information provided by Respondent revealed several potentially dangerous conditions relating to the Facility’s refrigeration system. The EPA communicated these findings with the Respondent after the Inspection and detailed these findings in the EPA’s Inspection Report provided to the Respondent on or about March 11, 2020. The potentially dangerous conditions identified by EPA are listed in the chart attached to and made part of this Agreement as Appendix A. Appendix A also explains how each of the conditions could lead to a release or inhibit the Facility’s ability to minimize the consequences of any release that might occur and includes examples of recognized industry standards of care that could feasibly reduce or eliminate the hazard. ALLEGED VIOLATIONS OF LAW |

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2025) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|

An ammonia leak occurred inside the machinery room of a public athletic club with indoor ice facilities. The leak happened during the decommissioning work of an ammonia refrigeration condenser by a licensed refrigeration contractor, which resulted in the facility enacting its Ammonia Release Emergency Protocol. The incident was likely caused by the contractor not properly purging and vacuuming the oil pot and dropping the leg to remove all the ammonia from the refrigeration system before cutting the pipe.

An ammonia leak occurred inside the machinery room of a public athletic club with indoor ice facilities. The leak happened during the decommissioning work of an ammonia refrigeration condenser by a licensed refrigeration contractor, which resulted in the facility enacting its Ammonia Release Emergency Protocol. The incident was likely caused by the contractor not properly purging and vacuuming the oil pot and dropping the leg to remove all the ammonia from the refrigeration system before cutting the pipe.